Risk analysis and machine safety

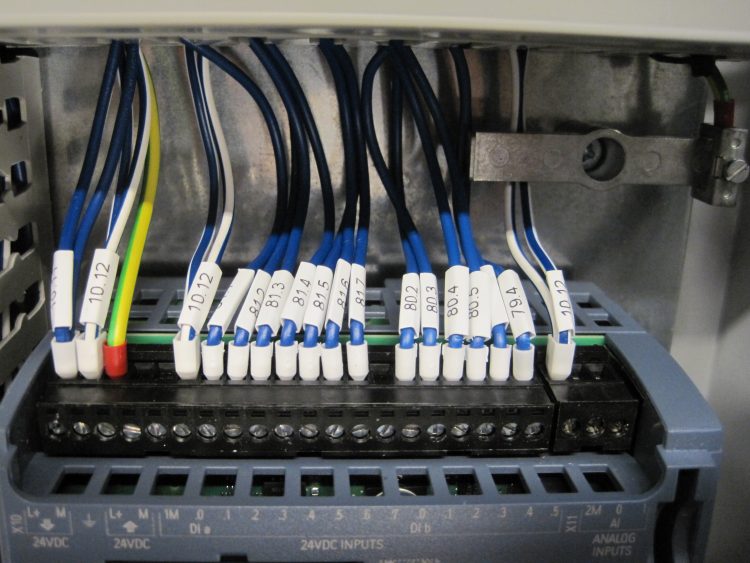

Regarding hardware design, DI-Teknik attaches great importance to risk analysis and machine safety. This refers to documentation and quality control in relation to people, products, production equipment, and the environment. Our hardware engineers perform a risk assessment based on an assessment of all relevant risks, where assumptions and uncertainties have been considered and described.

Safety at work

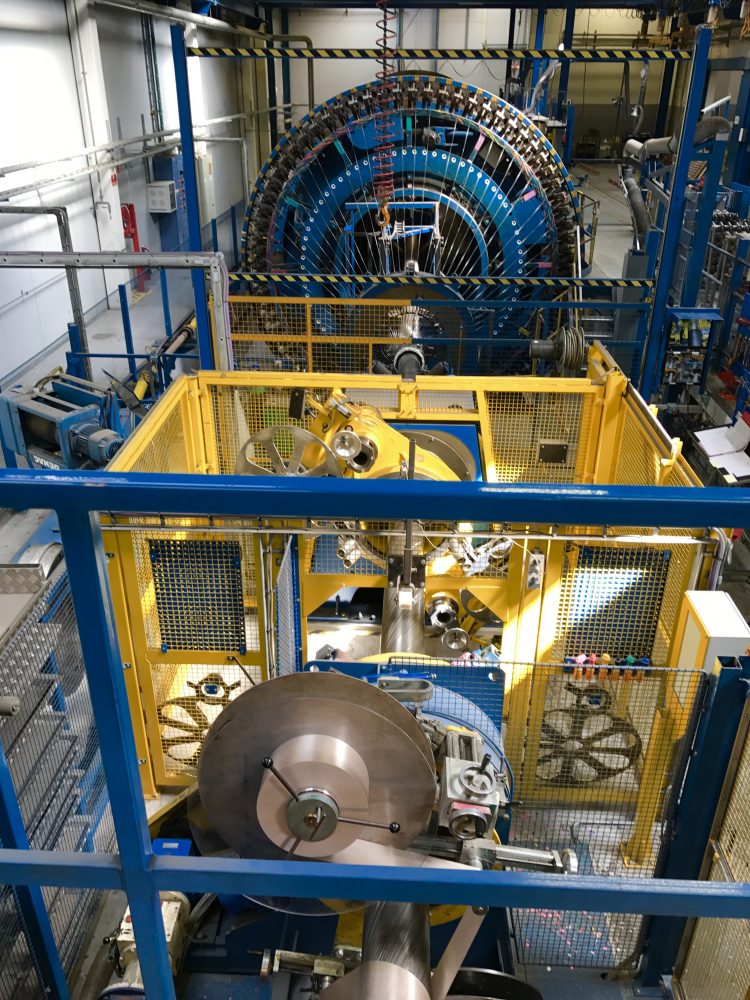

All new machines must comply with the Machinery Directive. On machines already operating, the Danish Working Environment Authority’s Order 1109 applies, and the owner of the machine is responsible for compliance. Prior to installing the necessary security, a risk assessment must be performed. The risk assessment ends with suggestions for, which solutions will be the most reasonable for each machine.

Solutions to safeguard the machine can be a solid shield, movable shields with a lock, light grille, two-hand operation, and many other protection options. This depends on the machine’s use and interior design.

We have TÜV Nord Certified Machine Safety Experts at your disposal

DI-Teknik has the necessary knowledge and experience to carry out a risk assessment in cooperation with the customer. And we subsequently perform the necessary measures on new machines, and improvements to existing machines, to comply with the applicable legal requirements.

We have several skilled TÜV North Certified Machinery Safety Experts (CMSE) employed in our company. They possess the right know-how in relation to machine safety, e.g. robotics, and process systems, as well as CE marking.

Contact information

Please contact us at our main telephone number +45 5667 0066 or via our contact form, and we will connect you to one of our responsible project engineers for assistance.